Hazardous Event refers to the sequence of malfunctions, errors, failures, and other conditions that can eventually lead to an unexpected or undesired release of material or energy from the process (i.e. an unplanned, uncontrolled loss of primary containment ‘LOPC’).

Hazardous events are generally analyzed by assessing the Risks associated with the Hazard. Risks are evaluated in three distinct stages:

- Hazard Identification – Main purpose of PHA activities.

- Risk Assessment – Generally done in conjunction with the PHA.

- Risk Management – This step occurs after the PHA completed.

Hazard Identification: PHA is the primary tool to identify process hazards, but there are also other ways where hazards could be identified as part of other activities, including: • Incident Investigations • Safety Audits • Facility Siting • Ergonomic Analysis • Job Safety Analysis (JSA), etc.

In general, the process of hazard identification can be lengthy and time consuming, and also it is very dependent on the activity or process being reviewed, and the people (team) reviewing it. One of the crucial steps of any hazard’s identification process is to select the right method and team.

Risk Assessment: After completion of hazards identification activity, it is common practice to conduct a risk assessment as part of the hazard identification process (known as PHA study). The most common technique used for risk assessment is qualitative approach, such as a risk matrix (Qualitative Risk Assessment).

However, there are also other ways to assess the risk, which also include the use of calculated modelling methods (Quantitative Risk Assessment, or QRA).

When assessing the consequence severity of a hazard, always take into consideration:

- What is being released?

- What is the magnitude and the duration of the release?

- What is the impacted area?

- Who could be in that affected area?

- How does the process design figure into the release?

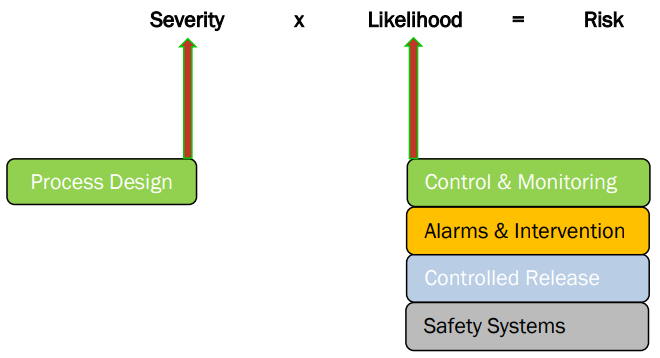

Always remember to disregard the safeguards (controls) when assessing the consequence severity, and consider the worst-credible case scenario impacting the upstream and downstream of process.

For likelihood assessment, consider these factors:

- Equipment integrity (maintenance, inspections, etc.)

- Operating personnel skills and competence (procedures (SOPs), training, etc.)

- Controls (safeguards)

Safeguards that are present, functional and effective, helps in decreasing the likelihood of the consequence.

Using the Qualitative Risk Analysis method for risk identification, the risk for the scenario is then compared to acceptable levels of risk. Usually, if the risk falls within acceptable region, no further actions required. And if the risk falls within unacceptable zone, suggestions (recommendations) made to reduce the risk to acceptable levels.

Risk Management: Managing risk is not simple, required planning and prioritizing to decide which actions to implement first, and when, is fundamental part of the risk management process. Risk management is based on the principles of ALARP: As Low As Reasonably Practical.

Basically, the main concept of ALARP is minimizing risks to a level at which any organization is comfortable, whereas available resources are capable to support and manage the risk. Taking as many risks as possible within the ALARP zone allows the organization to reduce its overall risk profile.

Concept of ALARP

The level or risk that describes any organization “comfort zone” is referred to as “acceptable risk”. The acceptable risk will be different for every organization, and may also even be different within different units or divisions of the same organization. Determining your level of acceptable risk depends on many things: regulations, industry, geography, societal considerations, economic considerations, and operating environment, etc.

Acceptable Risk

Understanding the acceptable level of risk of your organization is very important, for various reasons it help to:

- Minimize the unnecessary addition of risk reduction / mitigation measures

- Reduce the likelihoods of taking credit for ineffective risk reduction / mitigation measures

- Focus risk management efforts on only those measures that are truly essential to reducing overall levels of your operational risk.

- No further action required if a hazardous scenario is shown to achieve its acceptable risk level.

- Identify the ‘risk gap’ between the actual and acceptable risk level; and shows how much additional risk reduction effort will be required to reduce the gap.

Closing the Risk Gap

Application of the hierarchy of controls to determine what additional layers of protection can be added, or which existing layers can be modified, to help close the gap. There are many options available – select the method that works best within the parameters and constraints of your particular organization and situation.

Based on the risk gap, application of the various layers of protection can be applied until the risk can be reduced to the acceptable risk level. Use a variety of methods from different layers of protection, rather than multiple means from within a single layer. If unable to reduce the risk gap with provided controls, then large gaps may require a design change.

Always remember the basic definition of “risk”:

The final step in risk management is to revisit everything periodically, to ensure hazards are identified and risks monitored for any changes in the process. This is an ongoing, never-ending process cycle and commitment that remains in place until the end of the facility life.